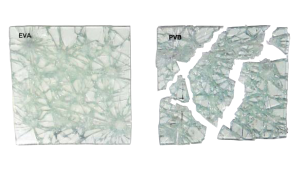

Laminated glass is a type of safety glass that is widely used in various industries, including building construction and transportation. One of the key components in laminated glass production is the interlayer material, which provides structural integrity and enhanced safety. Ethylene Vinyl Acetate (EVA) film is a popular choice for interlayer material due to its unique properties and advantages over Polyvinyl Butyral (PVB) film. In this article, we will explore the laminated glass production process using EVA film and discuss the benefits it offers.

- Properties of EVA Film:

- EVA film is produced with minimal moisture content, making it more resistant to moisture uptake compared to PVB film [3].

- EVA has superior adhesion properties to glass, and its bonding is irreversible, providing better resistance to moisture and adhesion reduction over time [3].

- EVA is a soft, transparent material with excellent flow characteristics, making it suitable for encapsulating various inserts in laminated glass, such as fabrics, metal meshes, and polyester films [3].

- EVA has lower water vapor transmission rate (WVTR) compared to PVB, resulting in improved product resistance against weathering conditions and reduced water penetration around edges and angles of laminated glass [6].

- Laminated Glass Production Process:

- EVA film and PVB film are supplied as films and can be easily handled and manipulated during the lamination process [6].

- The lamination process for EVA film involves a chemical cross-linking process, which transforms the film into a structured, thermoset product with the required mechanical properties [6].

- The chemical transformation of EVA can take place in small ovens with vacuum and temperature control, making the equipment cost lower compared to PVB lamination [6].

- Advantages of EVA Film in Laminated Glass Production:

- EVA film has lower water absorption compared to PVB, allowing for easier handling and storage outside of climatic chambers [6].

- The use of EVA film in laminated glass production offers excellent optical properties and the ability to dilute glass-glass dimensional and thermal dilatation tensions in different weathering environments [6].

- EVA film is particularly suitable for decorative and aesthetical applications in interior and exterior design, offering a wide range of colors and designs [3].

- EVA film is widely used in the photovoltaic market due to its high flow, crosslinking system, and good electrical properties [3].

Conclusion: In conclusion, the laminated glass production process with EVA film offers several advantages over PVB film. EVA film has distinct properties such as lower moisture uptake, superior adhesion to glass, and better resistance to moisture and adhesion reduction over time. The lamination process with EVA involves a chemical cross-linking process, resulting in a thermoset product with the required mechanical properties. EVA film is a versatile material suitable for various applications, including decorative and aesthetical uses. Its use in laminated glass production provides enhanced safety, durability, and design possibilities.